A world-first solar installing robot is being deployed to speed up the cleantech revolution.

Tell your state leaders to investigate using solar installation robots to accelerate the clean energy buildout in their states!

Touch or scan the QR code below to take today’s action in the app and earn trees!

Or take action on the Internet:

Reasons For Hope

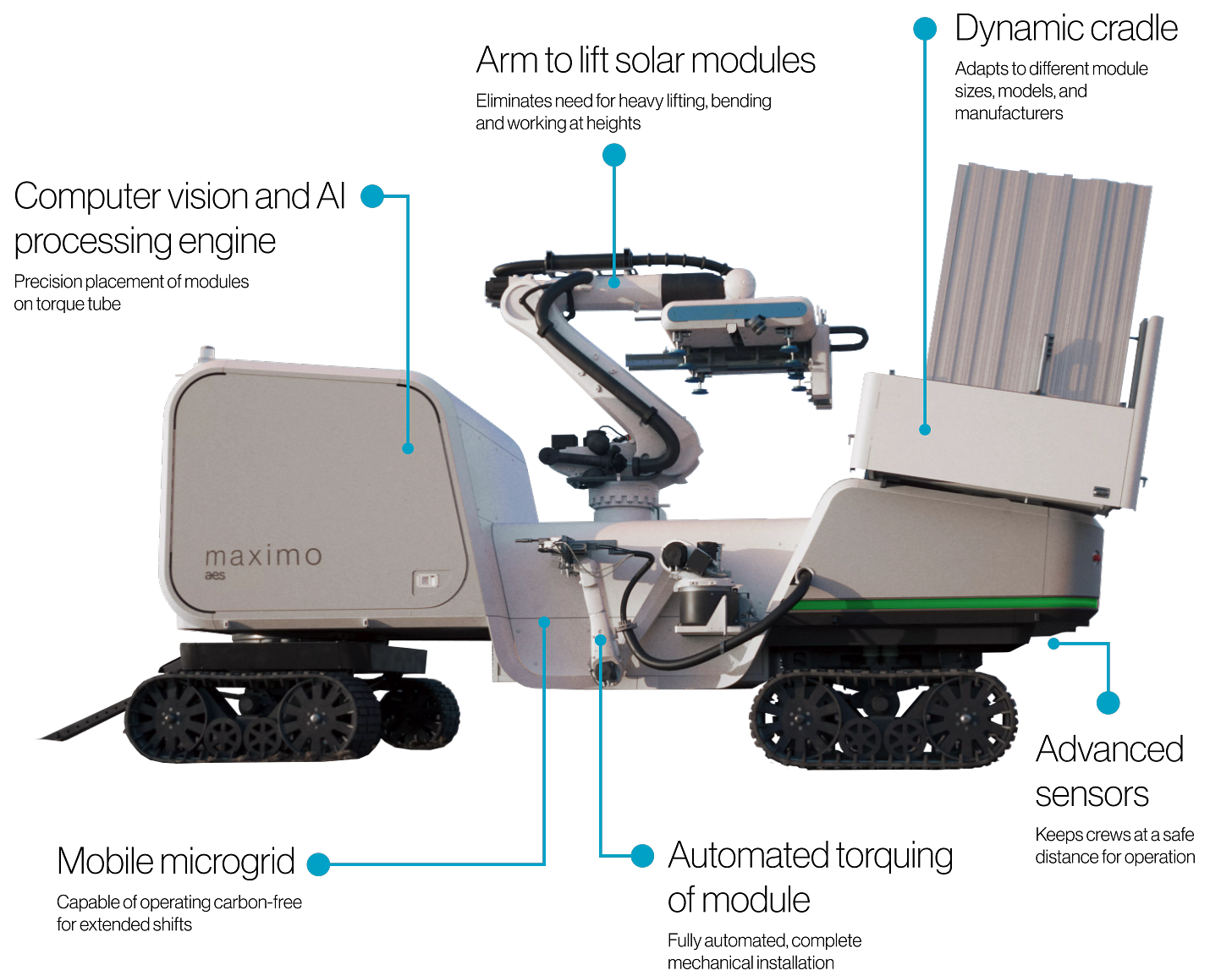

Renewables developer AES has just unveiled Maximo, the world’s first AI-enabled solar-installing robot, which they claim can reduce solar installation timelines and costs by up to 50%.

Maximo automates heavy lifting while using AI-powered computer vision to precisely place each solar panel, and AES reports that it can work around the clock and during extreme weather conditions.

“Maximo is the first proven solar installation robot on the market.”

-Andrés Gluski, CEO of AES.

The Maximo model has already installed 10 MW worth of solar panels in a series of previously unpublicized tests, including its first deployment to a grid-scale project when it helped out at the Oak Ridge Solar project in Louisiana.

“Maximo is supercharging the workforce, enabling the installation of solar panels in half the time and at half the cost. It utilizes some of the most advanced technology, to ensure the fastest and most precise installation in even the most challenging outdoor environments.”

-Deise Yumi Asami of AES, founder of the Maximo project.

Maximo is now starting work at the under-construction Bellefield project in Kern County, California (set to become another gigawatt-scale solar and battery farm) where the presence of the robot should help minimize the exposure of human work crews to extreme heat.

"Today, the US solar industry is setting an impressive pace, installing about 15,000 modules per hour, weighing one million pounds. Looking ahead, this installation rate is projected to reach 50,000 modules per hour by 2035.

In response to this exponential growth, we are scaling Maximo, deploying fleets of continually improving robots to empower our teams for faster and more competitive installations."

-Chris Shelton, AES Chief Product Officer.

This is pretty amazing stuff, and is an incredibly exciting sign of new opportunities to make our epic transition to a clean electron-powered civilization happen even faster! Policymakers need to know about the emerging potential of solar-installation robots.

https://oilfieldwitness.org/technical-limitations-of-satellite-and-regulations-in-stopping-methane/#comment-93

Without an army of motivated regulators armed with the equipment, regulation is a delay tactic. We also need strong enforcement with meaningful penalties and criminal charges with jail time for repeat offenders.

The industry publicly embraces regulation because they know it’s not realistic. And, even so, they fight it at every step. Meanwhile we are poking more holes and building more infrastructure that will go unregulated.

Methane is a volatile gas that they put inside steel infrastructure. Physics demands releases of the gas as it volatilizes “to protect equipment.” Currently, there is no magic bullet that makes it possible to produce oil and gas without releasing methane. That is why the industry, on one hand, claims they have stopped the pollution, while, with the other hand, they beg for more permits to pollute. The required permits to pollute are freely given, each allowing them to pollute tons of pollution each year.

There is no more time to delay. The best way to reduce methane is to keep it in the ground. We must stop allowing the industry to freely expand and we must rapidly transition to clean, renewable energy.